SHG series rake teeth rotary screen cleaner I. product introduction

SHG series rotary grid decontamination machine is a kind of special water treatment equipment which can continuously and automatically intercept and remove all kinds of sundries in the fluid. It can be widely used in urban sewage treatment. Water industry, power plant intake, as well as textile, food processing, papermaking, leather and other industries in the wastewater treatment process of the former screening equipment, is one of the advanced solid-liquid screening equipment.

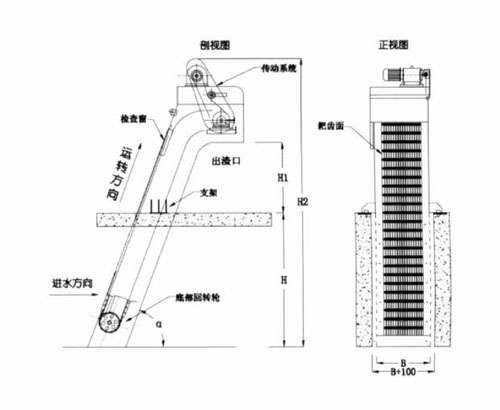

2、 How it works

SHG series rotary screen cleaner is a group of rotary screen chains assembled by a unique rake teeth. Driven by the motor reducer, the rake teeth chain rotates against the water flow direction to salvage the scum floating on the water surface. When the rake teeth chain is transferred to the upper part of the equipment, due to the guide of the groove wheel and the curved rail, the relative self-cleaning movement occurs between each group of rake teeth, and most of the solid materials fall down by gravity. The other part cleans up the debris stuck on the rake teeth by the reverse movement of the sweeper.

According to the flow direction, the rake chain is the same as the grid, and the rake tooth clearance assembled on the rake chain shaft can be selected according to the use conditions. When the rake teeth separate the solid suspended solids in the fluid, the flow of water can be ensured to flow smoothly. The whole working process is continuous or intermittent.

3、 Model specification

Model: shg-500-1000-800-5-70

SHG -- rotary grid cleaner

500 --- machine width 500mm

1000 --- canal depth

800 -- slag height

5 ------- rake tooth clearance

70 ------ inclination angle of installation body

4、 Product features

The equipment has the advantages of high automation, high separation efficiency, small power consumption, no noise and good corrosion resistance. It can ensure continuous and stable operation under the condition of unattended, and it is equipped with mechanical overload safety protection device. In case of equipment failure, the shear pin is cut, which can avoid overload work and damage of equipment components.

The equipment can adjust the operation interval of the equipment according to the user's needs to achieve periodic operation; it can automatically control the start and stop of the equipment according to the liquid level difference between the front and the back of the grid; and it has manual control function to facilitate maintenance. Users can choose according to different work needs.

Due to the reasonable structure design of the equipment, it has a strong self-cleaning ability when the equipment is working and will not jam, so the daily maintenance workload is very small.

5、 Technical parameters and selection

The equipment is customized according to the user's demand for water discharge, width and depth of civil canal, and the need for rake tooth clearance.

The equipment specification is divided into gf300-3600 according to the machine width. If the machine width is more than 1800mm, it will be made into parallel machine, and the middle part will share the wall panel. The gap of rake gear grid is divided into 1mm, 3mm, 5mm, 10mm, 15mm, 20mm, 30mm, 40mm, 50mm and other required specifications. The selection is based on the amount of water, lifting height, total amount of solid-liquid separation and the shape and particle size of the separated material. At the same time, different materials are selected.

The depth of the equipment trench is customized by the user. The depth can be customized according to the user's needs and the actual situation. Generally not less than 0.8m, not more than 15m.

6、 Outline dimension drawing