Summary:

Pressurized dissolved air floatation is widely used at home and abroad. The master pressurizes the raw water to 0.3 ~ 0.4MPa, at the same time, air is introduced to make the air dissolve in the water and reach the saturation value under the corresponding pressure state, and then suddenly reduces to the normal pressure. The air dissolved in the water is released from the water in the form of tiny bubbles, with the bubble diameter of about 20 ~ 100 μ M. the current basic process has all entered Water pressurized dissolved air flotation, part of water inlet pressurized dissolved air flotation and part of treated water return pressurized dissolved air flotation are composed of pressure pump, dissolved air tank, releaser, air flotation tank and other basic equipment.

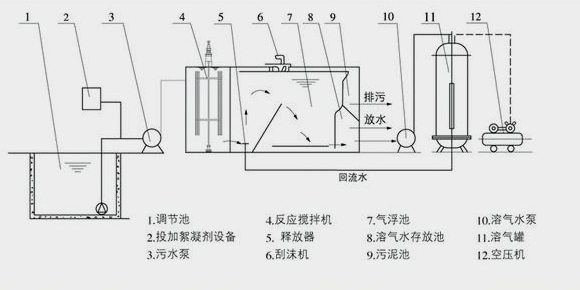

At present, it is widely used for partial treatment water reflux pressurized dissolved air flotation. Its process flow is as shown in the figure. In this method, part of the treated water (20-50%) is recycled and sent to the pressure dissolved air tank to make the air fully dissolved in the water, and then mixed with the flocculated raw water after passing through the releaser into the air flotation tank. The treatment effect of this method is stable, and can save a lot of energy consumption. It is widely used in sewage treatment process.

Features and application scope:

Pressure dissolved air flotation has the following advantages;

1. Under the condition of pressure, the air solubility and the number of air bubbles for air supply floating are more. To ensure the air flotation effect;

2. When the dissolved gas is suddenly depressurized, the bubbles are not only fine. The particle size is uniform. It has high density, stable floatation and little disturbance to liquid, so it is especially suitable for transporting flocs. , solid-liquid separation of fine particles;

3. The process and equipment are relatively simple and easy to manage and maintain;

4. In particular, the partial reflux type has remarkable and stable treatment effect, and can greatly save energy consumption.

Scope of application:

Dissolved air floatation machine is a new type of air floatation equipment which has been successfully developed by introducing foreign advanced technology and combining with China's national conditions and industry characteristics. The air floatation equipment is mainly used in the following aspects:

1. Removal of heavy metal ions (electroplating mixed wastewater treatment);

2. Oil refining and oil-water separation of all kinds of oily wastewater;

3. Degreasing and chroma removal of tannery wastewater;

4. Separation of biofilm after biological treatment of various kinds of sewage;

5. Sludge concentration (the treatment capacity is 20-30% of the equipment sewage treatment capacity);

6. Decolorization and impurity separation of printing and dyeing wastewater;

7. Algae removal in water supply engineering;

8. Casing processing wastewater treatment.

Process flow chart:

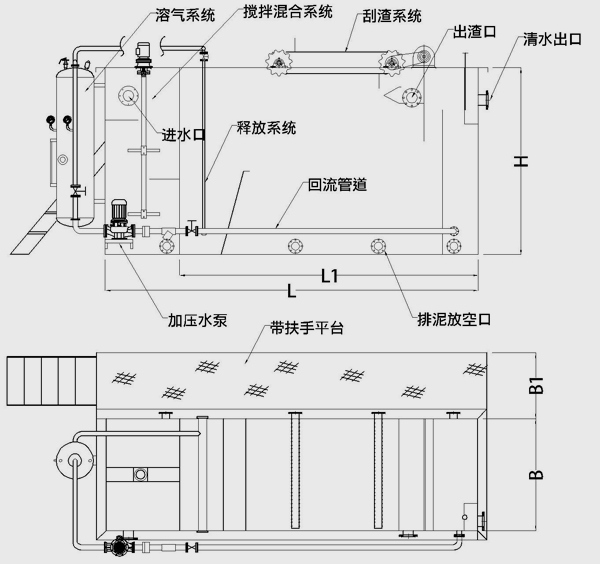

Outline diagram: