Introduction to MBR integrated equipment processing

MBR (membrane bioreactor) is a combined process combining biological treatment and membrane separation. A hollow fiber membrane module is placed in the bioreactor. The hollow fiber membrane for filtration is ultrafiltration membrane (UF) with a pore size range of 0.04 μ m, which is mainly used for the retention of suspensions and organics. It can maintain a certain concentration of microorganisms in the bioreactor and purify the sewage.

MBR membrane bioreactor is a new high-efficiency sewage treatment process which combines high-efficiency membrane separation technology with traditional activated sludge process. It uses MBR flat membrane module with unique structure to place it in the aeration tank. After aerobic aeration and biological treatment, the water is filtered by the pump through the filter membrane and then pumped out. MBR sewage treatment is quite different from the traditional sewage treatment method. Membrane separation device is used to replace the secondary sedimentation tank and tertiary treatment process in the traditional process. Thus, high quality effluent is obtained, which solves the problem that the effluent quality of traditional environmental protection equipment cannot meet the requirements of reclaimed water reuse. The water after MBR sewage treatment can be directly used as municipal water or further treated as various industrial water.

Due to the existence of MBR membrane, the ability of solid-liquid separation of the system has been greatly improved, so that the effluent, water quality and volume load of MBR membrane bioreactor have been greatly improved. After membrane treatment, the water quality standard is high (more than the national standard). After disinfection, the high-quality reclaimed water with high quality and biological safety can be directly used as a new water source. Due to the filtration of membrane, microorganisms are completely trapped in MBR membrane bioreactor, which realizes the complete separation of HRT and age of activated sludge and eliminates the problem of sludge bulking in traditional activated sludge process. MBR membrane bioreactor has the advantages of high pollutant removal efficiency, strong nitrification capacity, simultaneous nitrification, denitrification, good denitrification effect, stable effluent water quality, low excess sludge output, compact equipment, small floor area (only 1 / 3-1 / 2 of the traditional process), convenient incremental capacity expansion, high automation, simple operation, etc.

MBR membrane bioreactor module series has the advantages of compact structure, beautiful appearance, small floor area, low operation cost, stability and reliability, high automation, convenient maintenance and operation, etc. The effluent quality of MBR is better than that of reclaimed water. With the unique MBR flat membrane technology, it overcomes many shortcomings of the general hollow fiber membrane and is an advanced sewage treatment equipment. A series of membrane modules of MBR membrane bioreactor have formed a standardized series of products. Each module is composed of 50-150 standard flat membranes. It can also be designed independently according to the needs of users to meet the needs of users.

MBR integrated equipment is an integrated equipment that uses membrane bioreactor (MBR) for sewage treatment and reuse. It has all the advantages of membrane bioreactor: good effluent quality, low operation cost, strong system impact resistance, less sludge, high degree of automation. In addition, as an integrated equipment, it has a small floor area and is easy to integrate. It can not only be used as a small sewage recycling equipment, but also as the core treatment unit of a large sewage treatment plant (station). It is one of the hot spots in the field of sewage treatment, and has a broad application prospect.

Working principle of MBR equipment

Membrane bioreactor (MBR) is a new wastewater treatment technology which combines membrane separation technology and biotechnology. It uses the membrane separation equipment to intercept and retain the activated sludge and macromolecular organic matter in the biochemical reaction tank, thus eliminating the secondary sedimentation tank. As a result, the concentration of activated sludge is greatly increased. HRT and SRT can be controlled respectively, while the refractory substances are continuously reacted and degraded in the reactor.

Therefore, the membrane bioreactor (MBR) process greatly enhances the function of the bioreactor through membrane separation technology. Compared with the traditional biological treatment method, it is one of the new wastewater treatment technologies.

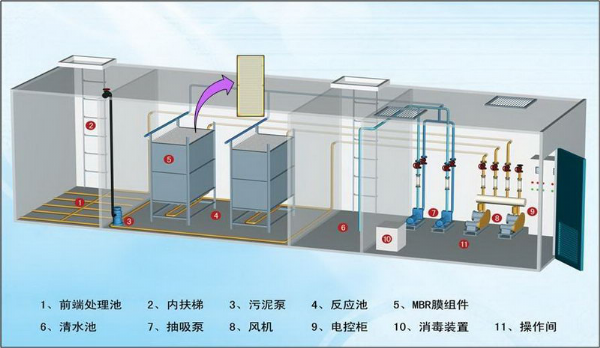

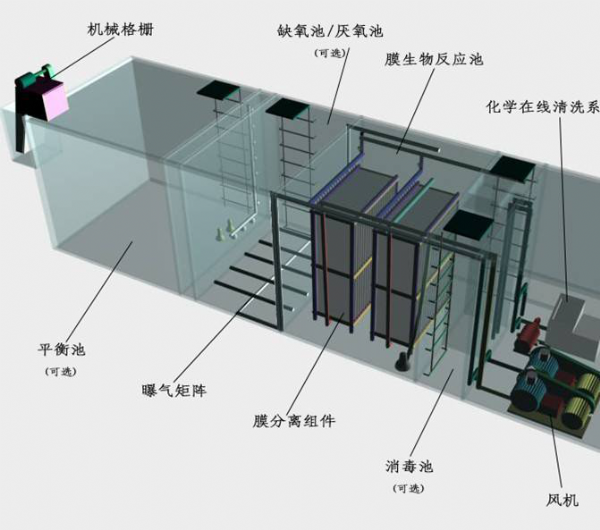

The basic structure of MRBR is shown in the figure below:

MBR equipment performance parameters

Influent water quality

The core component of MBR integrated equipment is membrane bioreactor, and the water quality requirements are as follows:

COD<500mg/L;

BOD5<300mg/L;

SS<100mg/L;

NH3-N<50mg/L;

Number of Escherichia coli < 10000 / L;

The integrated equipment can flexibly configure the process flow according to the raw water quality, so that the equipment has a wide range of applicability. It can directly treat domestic sewage and hospital sewage to meet the standard of domestic miscellaneous water. Effluent quality

The effluent quality meets the standard of miscellaneous domestic water:

COD<50mg/L;

BOD5<10mg/L;

SS<10mg/L;

NH3-N<10mg/L;

The number of Escherichia coli was less than 3 / L;

Typical process flow of MBR equipment

The process flow of MBR integrated equipment for domestic sewage treatment is as follows:

Grid → regulating tank → anaerobic tank → anoxic tank → membrane reaction tank → clear water discharge

This technology is an advanced sewage treatment technology. Its core is based on the immersion high-strength hollow fiber membrane separation and biological reaction technology, which integrates the suspension growth bioreactor and the ultrafiltration membrane separation system. The ultrafiltration membrane separation method replaces the secondary sedimentation tank and the sand filtration system in the traditional activated sludge treatment system. It is characterized by very good water quality, low suspended solids, CODCr, NH3-N, BOD5 and turbidity, and can be directly reused as miscellaneous water, such as domestic miscellaneous water other than drinking water, landscaping, car washing, etc.; industrial water, such as circulating cooling water or directly used as reverse osmosis water, production boiler make-up water and ultra pure water for electronic industry.

The ultrafiltration membrane is usually directly immersed in the aeration tank, and directly contacts with the biological reaction mixture. Through the negative pressure suction of the filter pump, the filtered water can achieve the solid-liquid separation through the external pressure hollow fiber membrane. The pressure difference of negative pressure suction is very low, the maximum head is only 2.2M, and the energy required for unit water treatment is small. During the filtration process, air is introduced at the bottom of the membrane through the blower. On the one hand, the turbulence generated by the rising of air flow has a scrubbing effect on the outer surface of the hollow fiber membrane, which can continuously remove the adhered solid substances on the membrane surface, prevent or reduce the pollution or blockage of the membrane; on the other hand, the air flow also has an aeration effect, which can provide most of the oxygen consumption required for biodegradation. The rest of the oxygen needed for biodegradation is also done by diffusion aeration system. The excess sludge produced in the biological reaction is discharged directly from the ultrafiltration membrane tank.

Main advantages of MBR equipment

MBR membrane bioreactor has the following outstanding advantages in the application of MBR sewage treatment and MBR water reuse engineering:

1. MBR membrane bioreactor has high pollutant removal efficiency and good effluent quality;

2. MBR membrane bioreactor has high sludge concentration, large volume load and small floor area;

3. MBR membrane bioreactor is conducive to the retention of slow-growing or efficient microorganisms, improving the nitrification effect of the system and the treatment capacity of refractory organics;

4. The production of excess sludge in MBR is low;

5. MBR membrane bioreactor is easy to realize automatic control and easy to operate and manage;

6. After treatment, SS and turbidity of discharged water are close to zero, which can be reused.

MBR (membrane bioreactor) process characteristics

1. Degradation of organic matter in sewage, nitrifying bacteria nitrify NH3-N to NO3 -, the removal rate of organic matter is more than 95%, and the removal rate of ammonia nitrogen is more than 97%.

2. The pretreatment process is simple, without a large amount of chemicals, and the operation process is simple;

3. The recovery rate is high, and the recovery rate of water can reach more than 99%. This flexibility allows the operator to reduce the "pressure" on the diaphragm by reducing the recovery rate when the quality of the inflow raw water deteriorates, but at the same time produce purified water of the same total amount and quality;

4. The system uses logical process monitoring system, including flow transmitter and pressure transmitter, etc. This highly controlled system approach can be used to design flexible systems and improve the minimum requirements for operator interfaces;

5. Air flushing ensures reliable operation under various inflow conditions;

6. The automatic recoil ensures that the overall membrane flux can be increased at a lower membrane pressure;

7. It occupies a small area, only 10-20% of the traditional technology;

8. Long service life, continuous operation time up to 70000 hours, broken wire rate less than 1%.